Today I got feature extraction working from real STEP files and set up CAM toolpath logic! Below is the breakdown of the steps (pun intended).

First learned how STEP files are set up and the type of information that's in them: everything is written in EXPRESS, and each line starts with a # and a number, and refers to a piece of information about the object (a line, surface, hole, etc). Basically, information on each component and how they are meant to be assembled together.

It took me quite a while to be able to read STEP files properly. Ran into mainly compiler issues, trying to read source files as executables, for example. (Source code is the human-readable instructions written in a programming language like C++, while an executable is the machine-readable program created by compiling that source code so the computer can run it.)

The main issue turned out to be goofball MacOS sandboxing my terminal & VSCode, aka not giving it permission to access my Downloads. Just had to change my settings and... voila! 1 solid, 1 shell, 61 faces, 168 edges and 112 vertices :)

After that it was very easy to analyze full shape hierarchies, create a new struct, find feature locations in 3D space, clean up the CLI (command line interface) output, and begin to generate CAM operations based on feature characteristics.

Some of the classes/enums I used were BrepAdaptor_Surface, TopExp_Explorer, TopAbs_FACE, TopoDS_Shape, GeomAbs_SurfaceType, UVBounds() and .Value(u, v).

THEN I decided I needed something a bit harder and got started on a visualizer - a 3D application layer so that I could render and see the toolpath, not just output lines on my terminal.

Initial setup was pretty easy, I installed Qt via Homebrew and linked it with OCCT in my CMake file. I also added logic for two different executables, and additional .cpp and .hpp files to support the new popup screen. But then again I had to wrestle with quite a few errors.

Specifically, WNT_Window was Windows only and it broke the build on my MacOS. Cocoa_Window(disp, winID) gave constructor mismatch, so I tried multiple things, like changing it to NSView and using Aspect_Window. I was able to solve this error, but was getting a stream of symbols instead of a proper build.

I have begun cockroach BCI experiments. The goal is to control where they go via an app on my phone. Welcome to the fam, Jack, Jill and Amy!

I have begun cockroach BCI experiments. The goal is to control where they go via an app on my phone. Welcome to the fam, Jack, Jill and Amy!

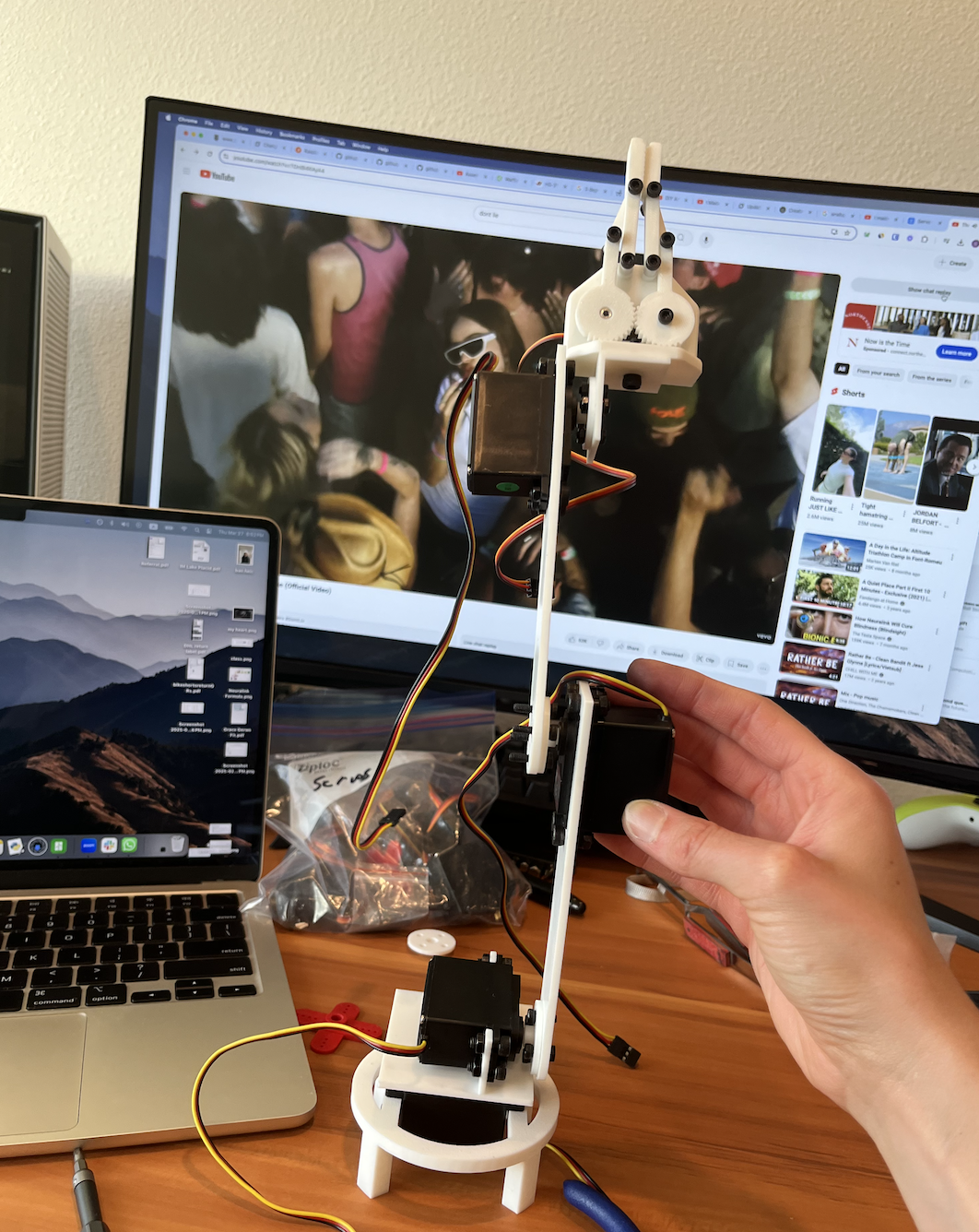

Assembled second arm of the robot. Did a deep dive on treasure hunting (pun intended). There is $200 billion on the ocean floor that no one has bothered to pick up or discover. Main barriers seem to be primarily legal - you have to get deals with governments to make sure they don't lay claim to all of it once you bring something up, and that you get a fair share.

Assembled second arm of the robot. Did a deep dive on treasure hunting (pun intended). There is $200 billion on the ocean floor that no one has bothered to pick up or discover. Main barriers seem to be primarily legal - you have to get deals with governments to make sure they don't lay claim to all of it once you bring something up, and that you get a fair share.

Removed gear from half of the servos. Assembled the leading arm of LeRobot. 3D printing additional parts.

Removed gear from half of the servos. Assembled the leading arm of LeRobot. 3D printing additional parts.

Today I got feature extraction working from real STEP files and set up CAM toolpath logic! Below is the breakdown of the steps (pun intended).

Today I got feature extraction working from real STEP files and set up CAM toolpath logic! Below is the breakdown of the steps (pun intended).

Set up dev environment for CAM, to take my CAD files to the next level.

Set up dev environment for CAM, to take my CAD files to the next level.

Spent 4h organizing my flat and unpacking everything I hadn't unpacked since I moved. Environment makes a huge difference. It was a mess and took way longer than I thought but now it looks sick. Yeah, I can lock myself in here to build 24/7 😎

Spent 4h organizing my flat and unpacking everything I hadn't unpacked since I moved. Environment makes a huge difference. It was a mess and took way longer than I thought but now it looks sick. Yeah, I can lock myself in here to build 24/7 😎

Finished first full version of the WaffleBot, assembled and connected it to the Raspberry Pi, and found that the HS-311 servos did not have enough torque / arm was too heavy so they couldn't lift it up properly.

Finished first full version of the WaffleBot, assembled and connected it to the Raspberry Pi, and found that the HS-311 servos did not have enough torque / arm was too heavy so they couldn't lift it up properly.

Am finding locking a bit difficult. So far am designing all of the components with holes for screws and manually screwing them in with hex nuts on the other side, but sometimes the parts are so small that it gets inconvenient to attach them. Don't quite understand yet how to drop a lock nut into a print / make threaded inserts, but I don't think I'll need that for this version.

Am finding locking a bit difficult. So far am designing all of the components with holes for screws and manually screwing them in with hex nuts on the other side, but sometimes the parts are so small that it gets inconvenient to attach them. Don't quite understand yet how to drop a lock nut into a print / make threaded inserts, but I don't think I'll need that for this version.

Learned how to design parts in context and import STEP files of specific components from the internet. Also learned fasten/revolute mates and made my first assembly.

Learned how to design parts in context and import STEP files of specific components from the internet. Also learned fasten/revolute mates and made my first assembly.

I had pain in my hip which turned out to be a torn labrum so I spent the last few days in the hospital / battling with insurance / getting ortho advice / recovering. So the last few days are blank but now I'm back!

I had pain in my hip which turned out to be a torn labrum so I spent the last few days in the hospital / battling with insurance / getting ortho advice / recovering. So the last few days are blank but now I'm back!